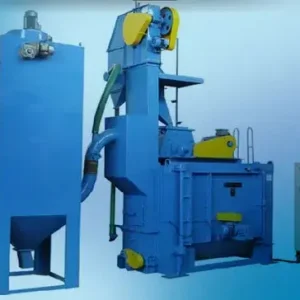

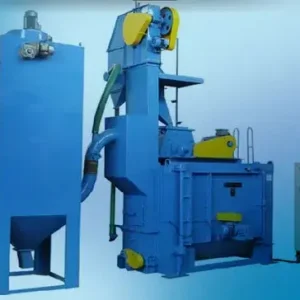

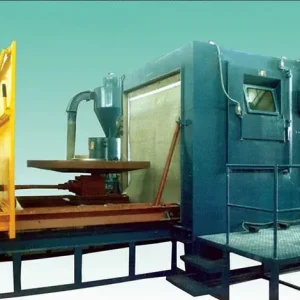

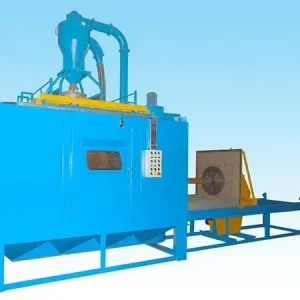

Shot blasting machines play a crucial role in surface preparation across various industries. Whether it’s removing rust, paint, or other surface contaminants, shot blasting machines are designed to deliver efficient and effective results. In this comprehensive guide, we will explore the role of shot blasting machines in surface preparation and the key benefits they offer.

- Surface Cleaning: Shot blasting machines are highly effective in cleaning surfaces by removing dirt, debris, rust, scale, and old coatings. The blasting process uses high-velocity abrasive particles to impact the surface, dislodging and removing unwanted materials. This results in a clean surface, free from contaminants, and ready for further treatment or coatings.

- Surface Roughening: Shot blasting machines are used to create a roughened surface profile, which is crucial for improving the adhesion of coatings or other surface treatments. By blasting the surface with abrasive particles, the machine imparts a controlled texture, increasing the surface area and providing better grip for subsequent coatings or bonding.

- Paint and Coating Removal: Shot blasting machines are widely employed to remove paint, coatings, and corrosion from various surfaces. The high-velocity abrasive particles effectively strip away old layers of paint or coatings, preparing the surface for fresh applications. This is particularly important in industries such as automotive, aerospace, and construction, where surfaces need to be free from old paint or coatings for optimal performance and aesthetics.

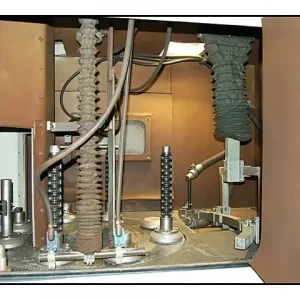

- Surface Deburring: Shot blasting machines are used for deburring metal parts, especially those with complex shapes or hard-to-reach areas. The abrasive particles effectively remove burrs, sharp edges, and other surface imperfections, resulting in smoother and safer components. This is crucial in industries such as metalworking and manufacturing, where precise and defect-free parts are essential.

- Surface Shot Peening: Shot peening is a specialized application of shot blasting that involves imparting compressive stresses to the surface of metal components. Shot peening helps improve the fatigue life and resistance to stress corrosion cracking of critical parts. Shot blasting machines are designed to deliver controlled and consistent shot peening processes, ensuring the desired surface properties are achieved.

- Surface Preparation for Welding: Shot blasting machines are used to prepare surfaces for welding by removing contaminants, rust, and scale. Proper surface preparation ensures strong and durable welds by providing clean and well-prepared surfaces for welding operations. Shot blasting machines offer an efficient and uniform method of surface preparation, contributing to improved weld quality and integrity.

- Surface Restoration and Refurbishment: Shot blasting machines are employed for the restoration and refurbishment of various surfaces, including historical monuments, bridges, and industrial equipment. The machines can effectively remove years of weathering, corrosion, and pollutants, revitalizing the surfaces and extending their lifespan. Shot blasting helps restore the original appearance, structural integrity, and functional properties of the surfaces.

The benefits of using shot blasting machines for surface preparation are numerous. They offer efficient and consistent results, reduce manual labor requirements, and provide a controlled and repeatable process. Additionally, shot blasting is a non-chemical and environmentally friendly method compared to other surface preparation techniques.

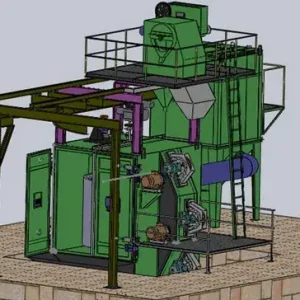

Shot blasting machine manufacturers in India

In conclusion, shot blasting machines play a vital role in surface preparation across industries. They clean, roughen, remove coatings, deburr, shot peen, and restore surfaces effectively and efficiently. By utilizing shot blasting machines, industries can achieve improved surface quality, better adhesion, and enhanced performance in their end products. The versatility and effectiveness of shot blasting machines make them indispensable tools in the surface preparation process.

Exploring the Wide Range of Shot Blasting Machines Offered by Indian Manufacturers

Shot Blasting Machines and Environmental Sustainability: Insights from Indian Manufacturers