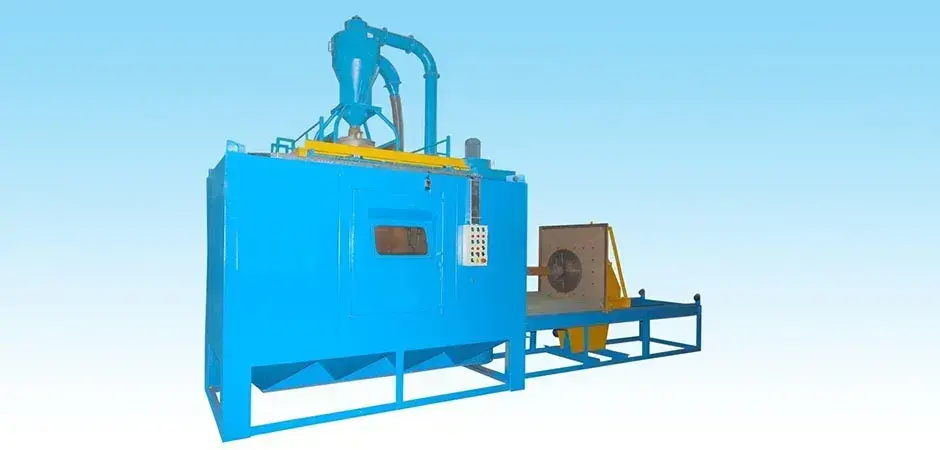

As one of the top Roll Etching Machine manufacturers in Delhi, Aerowheel specializes in designing and producing machines that deliver exceptional performance in the etching of roll surfaces. Our roll etching machines are ideal for industries such as steel, paper, textiles, and printing, where surface texture and precision are critical.

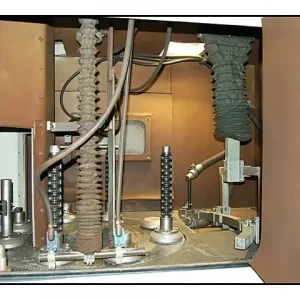

Our machines use advanced etching technologies to create uniform surface patterns on rolls, improving their functionality and performance. Whether you require custom designs or standard solutions, Aerowheel offers a range of roll etching machines to meet your specific needs.

Key Features:

- Precision Etching: Our roll etching machines provide consistent, high-precision surface texturing, ensuring optimal performance in your industrial applications.

- Robust Design: Built with durable materials and advanced technology to withstand continuous operation, ensuring long-term reliability and minimal maintenance.

- Customizable Solutions: Available in various sizes and configurations to meet the specific requirements of your business.

- User-Friendly Operation: Designed for ease of use, reducing downtime and increasing operational efficiency.

Why Choose Aerowheel for Roll Etching Machines in Delhi?

Best Shot Blasting Machine Manufacturers in India

Blasting Rooms at AeroWheel Surface Finishing: Precision and Quality in Every Detail

- Competitive Pricing: We offer cost-effective roll etching machines that provide excellent value for your investment, ensuring affordability without compromising on quality.

- Expertise in Manufacturing: With years of experience in the industry, Aerowheel is a trusted Roll Etching Machine manufacturer in Delhi. Our machines are built to meet both local and international standards, ensuring top-tier performance.

- After-Sales Support: Our relationship with clients extends beyond the purchase. We offer full after-sales service, including maintenance, spare parts, and expert support, ensuring your roll etching machine operates smoothly for years.

- Innovative Technology: Aerowheel integrates the latest etching technology into our machines, ensuring precision, durability, and efficiency, making us the go-to manufacturer in Delhi for roll etching solutions.

If you are looking for high-performance roll etching machines designed for precision and reliability, Aerowheel has the perfect solution for your needs. Contact us today for a personalized quote and to learn more about how our machines can enhance your surface texturing process.

Reviews

There are no reviews yet.