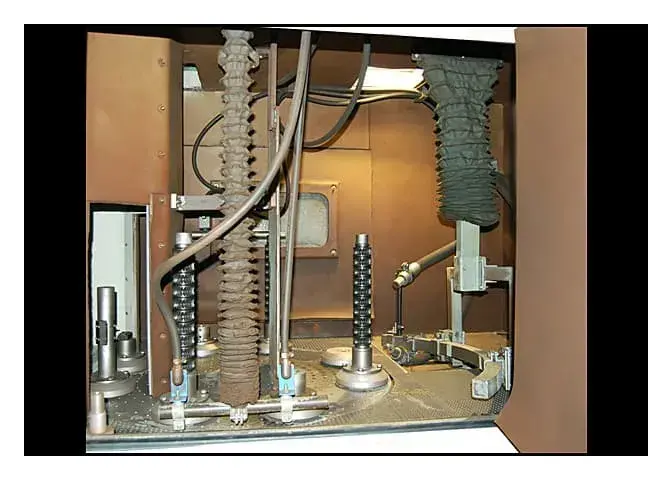

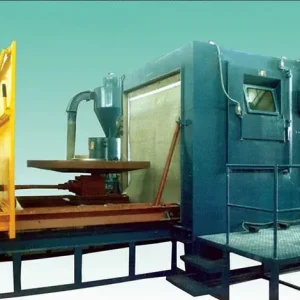

As a trusted Shot Peening Machine manufacturer in Delhi, AeroWheel Surface Finishing specializes in providing high-precision shot peening machines that are widely used in industries such as aerospace, automotive, defense, metalworking, and energy. Our shot peening machines are engineered to impart residual compressive stress on component surfaces, improving their fatigue strength, durability, and resistance to cracking.

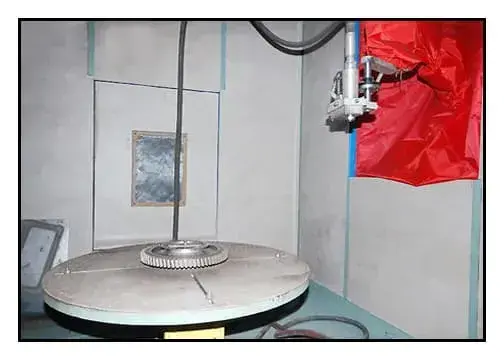

Our Shot Peening Machines use controlled high-speed media to precisely impact the surface of the component, ensuring uniform coverage and maximum effectiveness. These machines are essential for components such as gears, springs, and turbine blades, which are exposed to extreme stress and require enhanced fatigue resistance.

Key Features:

- Precision Peening: Designed for controlled, uniform shot peening, improving the fatigue life and durability of critical components.

- High-Efficiency Operation: Equipped with advanced control systems that ensure accurate shot velocity, angle, and coverage for optimal surface treatment.

- Durable Construction: Built with high-quality materials to withstand continuous operation in demanding industrial environments, ensuring long-term reliability.

- Customizable Solutions: Available in various configurations to suit the specific requirements of different industries, ensuring flexibility and precision.

Why Choose AeroWheel Surface Finishing for Shot Peening Machines in Delhi?

The Impact of Shot Blasting Machines on Corrosion Prevention: Insights from Indian Manufacturers

Sand Blasting Hopper at AeroWheel Surface Finishing: Efficiency and Precision in Surface Preparation

Shot Blasting Machines and Environmental Sustainability: Insights from Indian Manufacturers

- Cost-Effective Solutions: AeroWheel Surface Finishing provides affordable Shot Peening Machines that deliver excellent performance, helping industries enhance the strength and durability of their components without overshooting the budget.

- Industry Expertise: With years of experience as a Shot Peening Machine manufacturer in Delhi, we offer customized solutions that meet both local and international standards, ensuring top-tier results for your peening applications.

- After-Sales Support: We offer full after-sales service, including maintenance, spare parts, and technical support, ensuring that your machine continues to operate efficiently over time.

- Innovative Technology: Our shot peening machines incorporate the latest technology to provide precise, high-quality results, ensuring optimal performance for a wide range of components.

If you’re looking for a reliable and efficient Shot Peening Machine to improve the fatigue strength of your components, AeroWheel Surface Finishing is your trusted partner. Contact us today for a personalized quote and learn how our shot peening machines can enhance your production processes.

Reviews

There are no reviews yet.