Case Studies: Successful Projects by Shot Blasting Machine Manufacturers

Shot blasting machine manufacturers have been pivotal in numerous successful projects across various industries, showcasing their expertise and the effectiveness of their technologies. These case studies highlight the capabilities of leading manufacturers like AeroWheel Surface Finishing, Wheelabrator, Rosler, Goff Inc., and Sinto America, demonstrating how their shot blasting solutions have significantly improved production processes, product quality, and operational efficiency.

1. AeroWheel Surface Finishing: Enhancing Automotive Component Durability

Project Description: AeroWheel Surface Finishing collaborated with a leading automotive manufacturer to improve the durability and performance of critical engine components through shot peening.

- Objective: To increase the fatigue strength and stress resistance of engine components, thereby enhancing their lifespan and reliability.

- Solution: AeroWheel designed a custom shot peening machine tailored to the specific requirements of the automotive components.

- Implementation: The machine utilized controlled shot peening parameters to apply precise compressive stresses on the surface of the components.

Results:

- Improved Durability: The engine components exhibited a significant increase in fatigue strength and stress resistance.

- Enhanced Performance: The shot peening process resulted in smoother surface finishes, reducing friction and wear.

- Customer Satisfaction: The automotive manufacturer reported reduced failure rates and increased component lifespan.

2. Wheelabrator: Optimizing Surface Preparation for Wind Turbine Towers

Project Description: Wheelabrator partnered with a wind turbine manufacturer to enhance the surface preparation of wind turbine towers, ensuring optimal coating adhesion and corrosion resistance.

- Objective: To achieve a uniform and clean surface profile on large wind turbine towers for superior coating adhesion and longevity.

- Solution: Wheelabrator provided a state-of-the-art roller conveyor shot blasting system designed for large, cylindrical structures.

- Implementation: The system featured advanced dust collection and media recycling technologies to maintain efficiency and environmental compliance.

Results:

- Superior Surface Preparation: The towers achieved a consistent surface profile, improving coating adhesion and protection against corrosion.

- Operational Efficiency: The automated system reduced preparation time and labor costs.

- Environmental Compliance: The project maintained strict adherence to environmental regulations, minimizing dust emissions and waste.

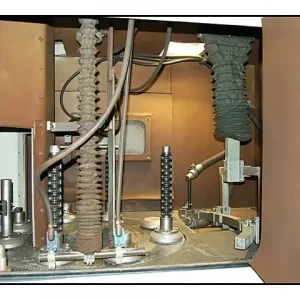

3. Rosler: Increasing Production Efficiency in Aerospace Manufacturing

Project Description: Rosler collaborated with an aerospace manufacturer to streamline the surface treatment process for aircraft components, enhancing production efficiency and component quality.

- Objective: To reduce processing time and improve the surface quality of aerospace components, ensuring they meet stringent industry standards.

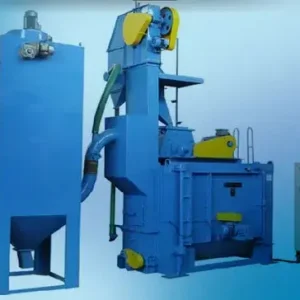

- Solution: Rosler developed a custom rotary table shot blasting machine with automated loading and unloading features.

- Implementation: The machine was integrated into the manufacturer’s existing production line, providing seamless and efficient surface treatment.

Results:

- Enhanced Surface Quality: The components met the highest standards for surface finish and cleanliness.

- Increased Throughput: The automated system significantly reduced processing time, increasing overall production capacity.

- Cost Savings: Improved efficiency and reduced labor costs led to substantial cost savings for the aerospace manufacturer.

4. Goff Inc.: Revitalizing Construction Equipment Components

Project Description: Goff Inc. assisted a construction equipment manufacturer in refurbishing worn-out components, restoring their functionality and extending their service life.

Taming the Blast: Demystifying Shot Blasting for the Uninitiated

Choosing the Right Shot Blasting Machine Manufacturer in India: Factors to Consider

A Comprehensive Guide to Tumblast Shot Blasting Machines

- Objective: To remove heavy rust, scale, and coatings from large construction equipment components, preparing them for refurbishment and recoating.

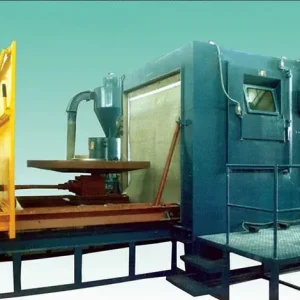

- Solution: Goff Inc. provided a high-capacity, tumble blast machine capable of handling large and heavy components.

- Implementation: The machine employed aggressive steel grit to achieve deep cleaning and surface profiling.

Results:

- Restored Functionality: The components were effectively cleaned and prepared, ready for refurbishment and recoating.

- Extended Service Life: The refurbished components demonstrated extended service life, reducing the need for frequent replacements.

- Sustainable Practice: The refurbishment process supported sustainable practices by reusing existing components rather than manufacturing new ones.

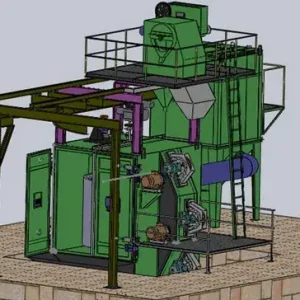

5. Sinto America: Improving Railcar Maintenance

Project Description: Sinto America partnered with a railcar maintenance company to enhance the surface preparation process for railcar refurbishment, ensuring durability and longevity.

- Objective: To remove old paint, rust, and contaminants from railcars, providing a clean surface for repainting and refurbishment.

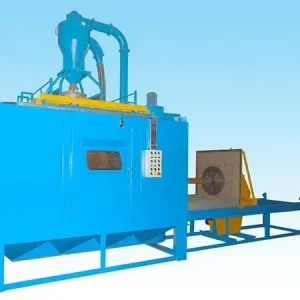

- Solution: Sinto America installed a high-efficiency shot blasting system designed for large and complex railcar structures.

- Implementation: The system featured an advanced dust collection unit and media recycling capabilities to maintain operational efficiency.

Results:

- Clean and Consistent Surfaces: The railcars achieved a clean, uniform surface, ideal for repainting and refurbishment.

- Increased Efficiency: The automated system reduced preparation time and improved overall maintenance efficiency.

- Durability and Longevity: The refurbished railcars exhibited enhanced durability and extended service life, reducing long-term maintenance costs.

Conclusion

These case studies demonstrate the significant impact that shot blasting machine manufacturers have on various industries. By providing customized, efficient, and environmentally friendly solutions, manufacturers like AeroWheel Surface Finishing, Wheelabrator, Rosler, Goff Inc., and Sinto America help their clients achieve superior surface preparation, improved product quality, and enhanced operational efficiency. These successful projects highlight the versatility and effectiveness of shot blasting technology in meeting diverse industrial needs and driving industry growth.