Shot blasting technology, an essential process in surface preparation and finishing, has a rich history and has evolved significantly over the years. This evolution reflects advancements in industrial techniques, materials, and the growing need for efficient and effective surface treatment methods across various industries.

Early Beginnings

Pre-Industrial Era

- Natural Abrasives: Before the industrial era, craftsmen used natural abrasives like sand and water to clean and finish surfaces manually. These methods were labor-intensive and time-consuming.

- Early Techniques: Simple tools and abrasive materials were used for tasks such as cleaning rust from metal objects, smoothing wood surfaces, and preparing stone for construction.

Industrial Revolution

19th Century Innovations

- Introduction of Machinery: The industrial revolution brought mechanization to surface treatment processes. The use of steam and later electric-powered machinery allowed for more efficient cleaning and finishing of metal surfaces.

- Sandblasting Invention: In the late 19th century, Benjamin Chew Tilghman is credited with inventing sandblasting. This process used compressed air to propel sand particles at high speeds, effectively cleaning and etching surfaces. This was a significant advancement, providing a faster and more uniform method of surface treatment.

Early 20th Century Developments

Emergence of Shot Blasting

- Transition from Sand to Shot: While sandblasting was effective, it had limitations in terms of safety and the type of finishes it could achieve. The introduction of metallic shot as an abrasive medium marked the beginning of shot blasting. Metallic shot provided a more durable and reusable abrasive, improving efficiency and reducing costs.

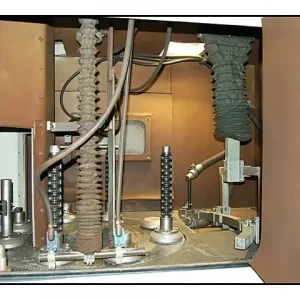

- Development of Blast Wheels: The invention of centrifugal blast wheels in the 1930s revolutionized the shot blasting process. Blast wheels used centrifugal force to hurl shot at high speeds, increasing the impact energy and cleaning effectiveness. This made shot blasting suitable for a wider range of applications, including heavy-duty industrial cleaning and surface preparation.

Mid 20th Century Innovations

Post-War Industrial Boom

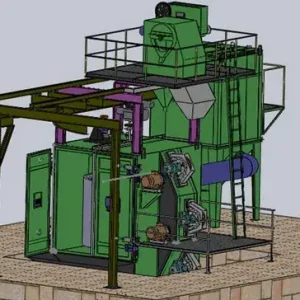

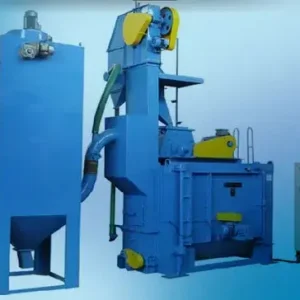

- Automated Systems: The post-World War II era saw significant advancements in automation. Automated shot blasting machines were developed, enabling continuous and consistent surface treatment processes. Conveyor systems, rotary tables, and tumblers were introduced, allowing for the efficient handling of large quantities of parts.

- Introduction of New Abrasives: The development of various types of abrasive media, including steel shot, grit, glass beads, and aluminum oxide, expanded the versatility of shot blasting. Each type of media had specific properties suited for different applications, from heavy-duty cleaning to fine surface finishing.

Late 20th Century to Present

Modern Technological Advancements

Maintenance Tips for Shot Blasting Machines

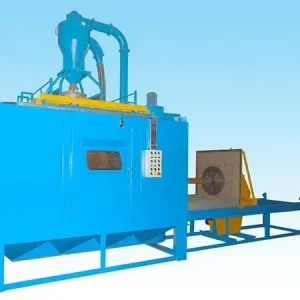

COOKWARE BLAST CLEANING PRIOR TO TEFLON COATING

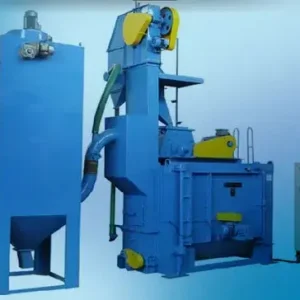

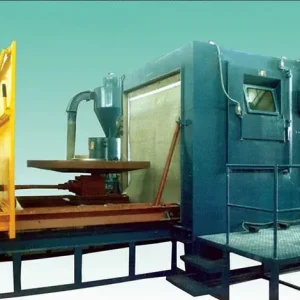

Conquer Surface Imperfections with AeroWheel's Airless Swing Table Shot Blasting Machine

- Computerization and Control Systems: The advent of computer technology brought significant improvements to shot blasting. Modern machines are equipped with computerized control systems that allow precise regulation of blasting parameters, such as media flow, blast pressure, and cycle times. This ensures consistent and repeatable results.

- Environmental and Safety Innovations: Increased awareness of environmental and safety concerns led to the development of advanced dust collection and filtration systems. These systems reduce airborne contaminants, improve air quality, and comply with stringent environmental regulations. Additionally, the use of enclosed blasting chambers minimizes exposure to abrasive media and enhances operator safety.

- Energy Efficiency: Recent innovations focus on improving energy efficiency and reducing the environmental impact of shot blasting. High-efficiency motors, variable speed drives, and energy recovery systems are now commonly used in modern shot blasting machines.

The Future of Shot Blasting Technology

Emerging Trends and Innovations

- Robotics and Automation: The integration of robotics in shot blasting is expected to increase precision and efficiency. Robotic systems can handle complex geometries and intricate surfaces, providing uniform blasting coverage.

- Smart Technology: The use of IoT (Internet of Things) and smart technology in shot blasting machines allows for real-time monitoring, predictive maintenance, and data analysis. This leads to improved machine uptime, reduced maintenance costs, and optimized performance.

- Sustainable Practices: Manufacturers are increasingly adopting sustainable practices, such as recycling abrasive media, using eco-friendly materials, and implementing energy-saving technologies. These efforts aim to minimize the environmental impact of shot blasting processes.

Conclusion

The history and evolution of shot blasting technology demonstrate a continuous journey of innovation and improvement. From its humble beginnings with manual abrasive techniques to the sophisticated, automated systems of today, shot blasting has become an indispensable process in various industries. As technology continues to advance, the future of shot blasting promises even greater efficiency, precision, and sustainability, meeting the ever-evolving demands of modern manufacturing and surface treatment applications.