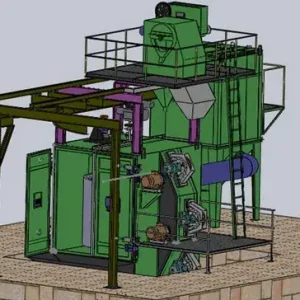

At AeroWheel Surface Finishing, our paint booth is the heart of our finishing operations, where components receive the final, transformative touch that brings them to life. The precision and care with which we operate our paint booth ensure that every component, whether large or small, emerges with a flawless, durable finish that meets the highest industry standards. In this article, we will explore the advanced technology, meticulous processes, and unparalleled expertise that make our paint booth a cornerstone of our commitment to quality.

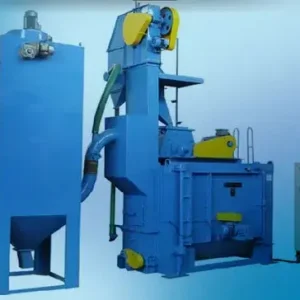

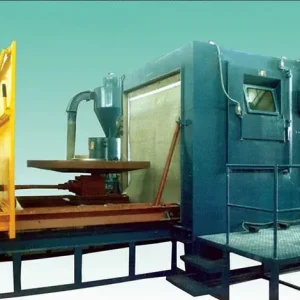

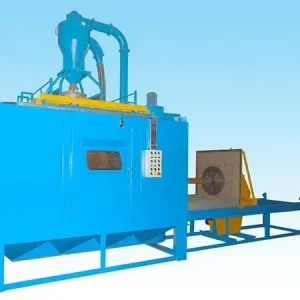

What is a Paint Booth?

A paint booth is a controlled environment designed specifically for the application of paint or coatings to various components. It is an essential part of the surface finishing process, providing a clean, contaminant-free space where coatings can be applied evenly and efficiently. At AeroWheel, our paint booth is equipped with state-of-the-art technology to ensure the best possible results, whether the job requires a simple protective coat or a complex multi-layered finish.

Advanced Technology in AeroWheel’s Paint Booth

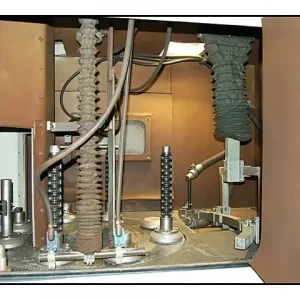

Our paint booth is equipped with the latest technology to ensure precision, efficiency, and safety in every operation. Here are some of the key features that set our paint booth apart:

1. High-Efficiency Spray Guns

Our paint booth is equipped with high-efficiency spray guns that provide an even application of paint across all surfaces of the component. These guns are designed to minimize overspray, ensuring that the paint is applied exactly where it’s needed, reducing waste, and improving the quality of the finish.

2. Climate Control Systems

Temperature and humidity control are critical factors in achieving a flawless paint finish. Our paint booth features advanced climate control systems that maintain optimal environmental conditions throughout the painting process. By controlling these variables, we can ensure that the paint adheres properly, cures evenly, and maintains its integrity over time.

3. Air Filtration and Ventilation

To maintain a contaminant-free environment, our paint booth is equipped with high-performance air filtration and ventilation systems. These systems remove dust, overspray, and fumes from the air, preventing any impurities from affecting the quality of the paint job. This not only results in a superior finish but also ensures a safer working environment for our technicians.

4. Automated Painting Systems

For projects that require high precision or large-scale production, our paint booth is equipped with automated painting systems. These systems allow for consistent, repeatable results, ensuring that every component is coated to the same high standard. Automation also improves efficiency, reducing the time required to complete each project without compromising quality.

The Painting Process: Excellence in Every Step

The painting process at AeroWheel is a carefully orchestrated procedure designed to achieve the highest standards of quality. Each step is executed with precision to ensure that the final product meets or exceeds our clients’ expectations.

1. Surface Preparation

Before painting begins, the surface of the component must be properly prepared. This may involve cleaning, sanding, or priming the surface to ensure that the paint adheres correctly. Proper surface preparation is crucial for achieving a smooth, durable finish.

2. Masking and Protection

Certain areas of the component may need to be protected from paint. Our technicians carefully mask these areas to prevent any unintended coating. This step is particularly important for components with complex geometries or those requiring multiple finishes.

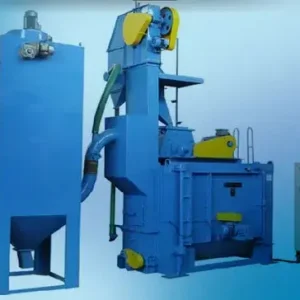

How to Increase the Efficiency of Your Shot Blasting Machine

Jodhpur's Abrasive Edge: Top Sand Blasting Machine Manufacturers for Every Need

3. Application of Paint

Once the surface is prepared and masked, the paint is applied using our high-efficiency spray guns. The paint is applied in thin, even layers, with each layer allowed to dry before the next is applied. This layered approach ensures a smooth, uniform finish that is both aesthetically pleasing and highly durable.

4. Curing and Drying

After the paint has been applied, the component is moved to a curing area where the coating is allowed to dry and harden. The curing process is carefully controlled to ensure that the paint achieves its full strength and durability. Depending on the type of paint used, this process may involve heat, UV light, or simply time.

5. Final Inspection and Quality Control

Once the paint has cured, the component undergoes a final inspection. Our quality control team checks for any imperfections, such as runs, drips, or uneven coverage. Any defects are corrected immediately to ensure that the final product meets our high standards of quality.

Why Choose AeroWheel’s Paint Booth for Your Finishing Needs?

Choosing AeroWheel for your painting and coating needs comes with numerous benefits. Our paint booth is not just a facility; it’s a commitment to excellence that reflects in every component we finish.

- Precision and Consistency: Our advanced technology and meticulous processes ensure that every component is painted to the highest standard, with consistent results across all surfaces.

- Efficiency and Speed: Our automated systems and high-efficiency equipment allow us to complete projects quickly and efficiently, without sacrificing quality.

- Customization and Flexibility: We understand that every project is unique, and we offer a range of customizable options to meet your specific requirements. Whether you need a glossy finish for aesthetics or a robust coating for protection, we have the expertise to deliver.

- Environmental Responsibility: Our paint booth is designed with sustainability in mind. We use eco-friendly paints and coatings wherever possible, and our advanced filtration systems reduce emissions and waste.

Industries We Serve

AeroWheel’s paint booth serves a diverse range of industries, each with its own set of requirements and standards. Our ability to deliver high-quality finishes across various applications makes us a trusted partner in the following sectors:

- Aerospace: In the aerospace industry, surface finishes are critical for both performance and aesthetics. Our paint booth ensures that components meet the exacting standards required for aerospace applications.

- Automotive: The automotive industry demands high-quality, durable finishes that can withstand harsh conditions. Our paint booth delivers the perfect balance of aesthetics and protection for automotive components.

- Marine: Marine environments are particularly harsh, requiring coatings that can resist corrosion and wear. Our paint booth provides the durable finishes needed to protect components in these challenging conditions.

- Industrial Equipment: For industrial equipment, a robust, long-lasting finish is essential. Our paint booth is capable of applying coatings that protect against wear, corrosion, and other forms of damage, ensuring the longevity of the equipment.

Conclusion

The paint booth at AeroWheel Surface Finishing is a testament to our dedication to quality, precision, and innovation. With advanced technology, skilled technicians, and a commitment to excellence, we deliver finishes that not only meet but exceed industry standards. Whether you’re in aerospace, automotive, marine, or industrial sectors, AeroWheel’s paint booth is the ideal solution for all your surface finishing needs.