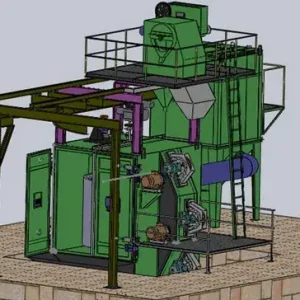

Shot blasting machines play a crucial role in enhancing productivity and efficiency across various industries. These machines are used to clean, descale, and prepare surfaces for further treatment, such as painting, coating, or bonding. In India, shot blasting machine manufacturers have been at the forefront of driving advancements in technology and innovation, leading the way in boosting productivity and efficiency.

Indian manufacturers of shot blasting machines have been proactive in understanding the evolving needs of industries and developing cutting-edge solutions to meet those requirements. They have invested in research and development to create machines that offer high-performance capabilities, improved automation, and increased throughput.

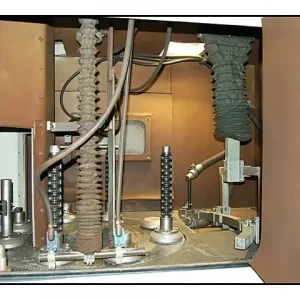

One of the key factors contributing to the productivity of shot blasting machines is the integration of advanced control systems. Indian manufacturers have implemented intelligent control panels and automation features that enable precise control over blasting parameters, such as speed, angle, and shot flow rate. This level of control ensures consistent and uniform surface treatment, resulting in higher productivity and improved quality of finished products.

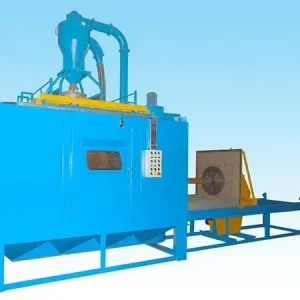

Furthermore, Indian manufacturers have focused on enhancing the efficiency of shot blasting machines through optimized designs and energy-saving features. They have introduced efficient blast wheel configurations, airflow systems, and abrasive recycling mechanisms that minimize energy consumption and maximize the utilization of abrasives. By reducing waste and optimizing process efficiency, these machines help industries achieve significant cost savings while maintaining high productivity levels.

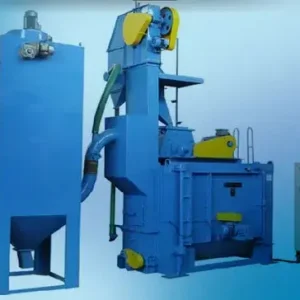

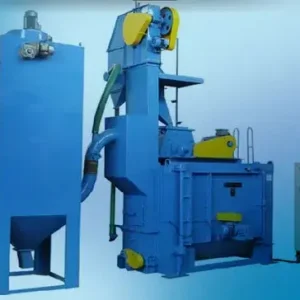

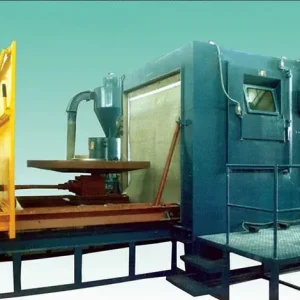

Another area where Indian manufacturers have excelled is in the development of customized shot blasting solutions. They understand that different industries and applications have unique requirements. Therefore, they offer a wide range of shot blasting machine variants, including table type, tumble type, hanger type, and continuous type, among others. These machines can be tailored to specific workpiece sizes, shapes, and production volumes, enabling industries to achieve optimal productivity and efficiency.

Indian shot blasting machine manufacturers also prioritize the use of high-quality materials and components, ensuring the durability and longevity of their machines. This results in reduced downtime and maintenance costs, contributing to overall productivity gains for end-users.

Moreover, Indian manufacturers have established strong after-sales support networks, providing timely technical assistance, spare parts availability, and maintenance services. This comprehensive support ensures that shot blasting machines continue to operate at peak performance, minimizing disruptions and maximizing productivity.

Benefits of Using Shot Blasting Machines

Tips for choosing Abrasive Blasting Media

SHOT PEENING PROCESS AND MACHINES

Shot blasting machine manufacturers in India

The relentless focus on productivity and efficiency by Indian manufacturers has made them trusted partners for industries seeking to enhance their surface treatment processes. Their expertise, technological advancements, and commitment to customer satisfaction have positioned them as leaders in the shot blasting machine market.

In conclusion, Indian manufacturers of shot blasting machines are driving productivity and efficiency gains for industries through their innovative solutions. By leveraging advanced control systems, optimizing designs, offering customization options, and providing robust after-sales support, these manufacturers are empowering industries to achieve higher productivity levels and improved overall efficiency. As a result, Indian manufacturers are playing a pivotal role in the growth and success of various sectors that rely on shot blasting for surface treatment.