Indian manufacturers have established themselves as leading providers of shot blasting machines, offering a wide range of options to cater to diverse industrial needs. These machines are designed to clean, prepare, and treat surfaces efficiently and effectively. Let’s explore the extensive range of shot blasting machines offered by Indian manufacturers:

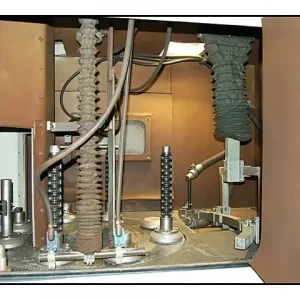

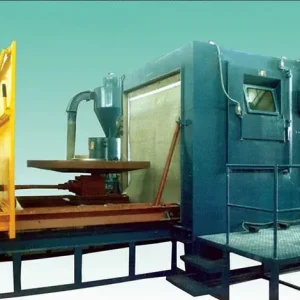

- Table Type Shot Blasting Machines: These machines feature a rotating table that holds the workpiece while the blasting operation takes place. They are suitable for small to medium-sized components and offer precise control over the blasting process.

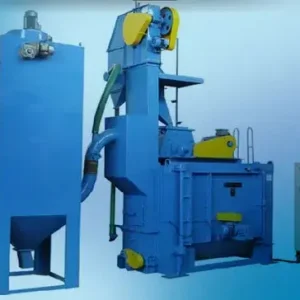

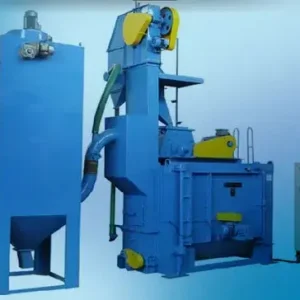

- Tumble Type Shot Blasting Machines: Tumble-type machines are designed for batch processing of smaller workpieces. The workpieces are placed inside a rotating drum, ensuring uniform and thorough blasting.

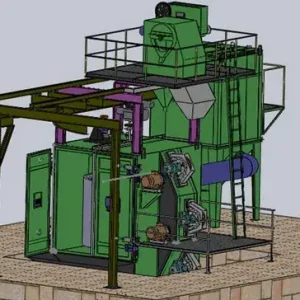

- Hanger Type Shot Blasting Machines: Hanger-type machines are ideal for larger and heavier workpieces. The workpieces are suspended from an overhead conveyor system and exposed to abrasive media from multiple angles, providing comprehensive surface treatment.

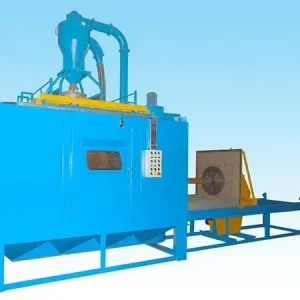

- Continuous Shot Blasting Machines: These machines are designed for high-volume production environments, offering continuous material flow through the blasting chamber. They are commonly used for treating long profiles, pipes, and structural components.

- Spinner Hanger Shot Blasting Machines: Spinner hanger machines combine the features of hanger-type and tumble-type machines. The workpieces are hung on a rotating hook, and the blasting is performed by a rotating blast wheel, ensuring efficient and uniform cleaning.

- Conveyor Shot Blasting Machines: Conveyor machines utilize a continuous belt or roller system to move the workpieces through the blasting chamber. They are highly automated, enabling efficient processing of large volumes of components.

- Multi-Table Shot Blasting Machines: Multi-table machines feature multiple rotating tables, allowing for simultaneous processing of different workpieces. This configuration enhances productivity and versatility.

- Shot Peening Machines: Shot peening machines use the shot blasting principle to induce compressive stress on the surface of metal components, improving fatigue resistance and prolonging the component’s lifespan.

- Blast Rooms: Indian manufacturers also offer blast rooms, which are enclosed spaces equipped with shot blasting machines. Blast rooms provide a controlled environment for blasting larger components or batches of components.

- Customized Shot Blasting Machines: Indian manufacturers understand that industries have unique requirements. They offer customization options to tailor shot blasting machines according to specific applications, workpiece sizes, and production volumes.

Indian manufacturers of shot blasting machines prioritize quality, durability, and performance. They utilize high-grade materials, advanced control systems, and efficient blast wheels to ensure optimal results and customer satisfaction.

Shot blasting machine manufacturers in India

With their extensive range of shot blasting machines, Indian manufacturers have become trusted partners for industries across various sectors, including automotive, aerospace, construction, foundries, and metalworking. These machines empower businesses to achieve efficient and effective surface treatment, enhancing product quality and productivity.

The Role of Shot Blasting Machines in Surface Preparation: A Comprehensive Guide

In conclusion, Indian manufacturers offer a comprehensive selection of shot blasting machines, catering to the diverse needs of different industries. From table type and hanger type machines to tumble type and continuous systems, these machines provide efficient and reliable surface treatment solutions. With their commitment to customization, quality, and innovation, Indian manufacturers continue to be at the forefront of the shot blasting machine market, delivering cutting-edge solutions to industries worldwide.