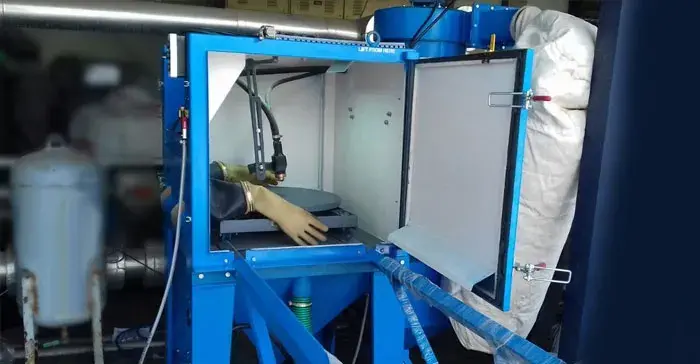

As a trusted name among Suction/Vacuum Blast Cabinet manufacturers in Delhi, AeroWheel Surface Finishing delivers cutting-edge solutions for industries requiring precise surface treatment. Our suction and vacuum blast cabinets are perfect for industries such as automotive, aerospace, metalworking, and fabrication, where efficient surface cleaning and preparation are essential for enhancing the quality of the finished product.

The Suction/Vacuum Blast Cabinets are designed to offer high-speed, dust-free blasting, ensuring a clean working environment and superior surface finishes. With customizable configurations, AeroWheel Surface Finishing’s blast cabinets provide flexibility for different materials and blasting requirements.

Key Features:

- High-Efficiency Blasting: Our suction/vacuum blast cabinets offer efficient surface cleaning, ideal for removing rust, paint, and other contaminants from surfaces.

- Dust-Free Operation: Equipped with advanced dust collection systems that ensure a cleaner work environment, making the operation safe and eco-friendly.

- Customizable Design: Available in different sizes and configurations to meet the specific requirements of various industries.

- Low Maintenance: Built with durable components that require minimal maintenance, ensuring long-term performance and reliability.

Why Choose AeroWheel Surface Finishing for Suction/Vacuum Blast Cabinets in Delhi?

How Shot Blasting Machines Work?

The cost-effectiveness of shot blasting compared to other surface preparation methods.

Taming the Blast: Demystifying Shot Blasting for the Uninitiated

- Competitive Pricing: AeroWheel Surface Finishing offers cost-effective suction/vacuum blast cabinets without compromising on quality, making it an ideal choice for businesses seeking efficient solutions at affordable prices.

- Local Expertise: As a leading Suction/Vacuum Blast Cabinet manufacturer in Delhi, we understand the specific needs of industries in the region, offering tailored solutions that meet both national and international standards.

- Comprehensive Support: We provide full after-sales service, including spare parts, maintenance, and technical support, ensuring your blast cabinet operates at peak performance throughout its lifecycle.

- Advanced Technology: Our blast cabinets are designed with the latest technology, offering superior blasting performance, durability, and ease of use, making us a preferred choice for industries in Delhi.

If you’re looking for a high-performance suction/vacuum blast cabinet to optimize your surface cleaning process, AeroWheel Surface Finishing has the right solution for you. Contact us today for a customized quote and let us help you enhance your industrial processes with our state-of-the-art equipment.

Reviews

There are no reviews yet.