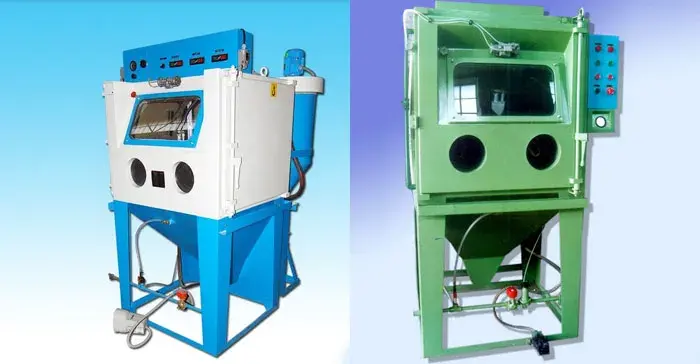

As one of the leading Wet Blast Cabinet manufacturers in Delhi, AeroWheel Surface Finishing specializes in advanced wet blasting technology designed for superior surface treatment. Our wet blast cabinets are ideal for industries such as aerospace, automotive, medical, and metalworking, where a dust-free environment and smooth surface finishes are critical.

Our wet blast cabinets use a combination of water and abrasive media to effectively clean, descale, and prepare surfaces without generating dust, making them perfect for sensitive environments. Whether you’re looking for a standard solution or a customized machine, AeroWheel Surface Finishing offers a wide range of wet blast cabinets to meet your specific needs.

Key Features:

- Dust-Free Operation: The wet blasting process eliminates dust, making it ideal for environments where cleanliness is essential.

- Precise Surface Finishing: Provides a smooth, even surface treatment, perfect for delicate components and high-precision industries.

- Corrosion Prevention: The use of water in the blasting process helps prevent surface corrosion, extending the life of the treated components.

- Customizable Design: Available in various sizes and configurations to suit your unique industrial requirements, ensuring maximum flexibility and efficiency.

Why Choose AeroWheel Surface Finishing for Wet Blast Cabinets in Delhi?

Customization Options Available from Shot Blasting Machine Manufacturers

COOKWARE BLAST CLEANING PRIOR TO TEFLON COATING

- Affordable and Competitive Pricing: AeroWheel Surface Finishing offers cost-effective wet blast cabinets that combine performance and value, making them an ideal choice for businesses in Delhi.

- Industry Expertise: With years of experience in surface finishing, AeroWheel Surface Finishing is recognized as a trusted Wet Blast Cabinet manufacturer in Delhi. Our machines are designed to meet the highest industry standards.

- After-Sales Support: We provide comprehensive after-sales services, including spare parts, maintenance, and expert technical support, ensuring your wet blast cabinet operates efficiently for years.

- Innovative Technology: Our wet blast cabinets are equipped with the latest technology, ensuring precise surface cleaning, reduced wear on components, and improved operational efficiency.

If you are looking for a reliable Wet Blast Cabinet solution to enhance your surface treatment process, AeroWheel Surface Finishing is the manufacturer you can trust. Contact us today for a customized quote and discover how our wet blast cabinets can improve your production capabilities.

Reviews

There are no reviews yet.