- As one of the most trusted Rotary Indexing Machine manufacturers in Delhi, AeroWheel Surface Finishing specializes in designing machines that offer enhanced productivity through automated indexing and precise positioning. Our rotary indexing machines are ideal for industries such as automotive, electronics, metalworking, and assembly lines, where high-speed, efficient processing is essential.

Our rotary indexing machines are known for their reliable and smooth operation, enabling businesses to increase throughput while maintaining accuracy in multi-station processes. Whether you need a standard configuration or a fully customized machine, AeroWheel Surface Finishing offers solutions tailored to your business needs.

Key Features:

- High-Precision Indexing: Ensures accurate and repeatable positioning for multi-station processing, maximizing efficiency and quality.

- Durable Construction: Built with high-quality materials and advanced engineering to withstand continuous heavy-duty operation, ensuring long-term performance.

- Customizable Options: Available in various sizes, load capacities, and configurations to fit the specific needs of your production line.

- Advanced Control Systems: Integrated with state-of-the-art control systems to ensure smooth and precise operation, reducing downtime and increasing efficiency.

Why Choose AeroWheel Surface Finishing for Rotary Indexing Machines in Delhi?

Benefits of Using Shot Blasting Machines

Difference between Shot Blasting And Sand Blasting Machines?

The cost-effectiveness of shot blasting compared to other surface preparation methods.

- Affordable Pricing: AeroWheel Surface Finishing offers competitive pricing for high-quality rotary indexing machines, providing excellent value for businesses of all sizes.

- Expertise and Innovation: With years of experience in the industry, AeroWheel Surface Finishing is a leading Rotary Indexing Machine manufacturer in Delhi. Our machines are built to meet the highest industry standards and incorporate the latest technologies for maximum efficiency.

- Comprehensive Support: We offer full after-sales service, including maintenance, spare parts, and technical support, ensuring that your machine runs at peak performance throughout its life.

- Tailored Solutions: Our rotary indexing machines can be customized to meet your specific production needs, ensuring seamless integration into your existing workflow.

If you’re looking for a reliable and efficient Rotary Indexing Machine to streamline your production process, AeroWheel Surface Finishing is your ideal partner. Contact us today for a customized quote and learn how we can enhance your operational efficiency with our cutting-edge solutions.

- As one of the most trusted Rotary Indexing Machine manufacturers in Delhi, AeroWheel Surface Finishing specializes in designing machines that offer enhanced productivity through automated indexing and precise positioning. Our rotary indexing machines are ideal for industries such as automotive, electronics, metalworking, and assembly lines, where high-speed, efficient processing is essential.

Rotary Indexing Machine Manufacturers in Delhi

Rotary Indexing Machine Manufacturers in Delhi

AeroWheel Surface Finishing is a leading Rotary Indexing Machine manufacturer in Delhi, providing high-precision machines designed for fast and efficient multi-station processing. Our machines are engineered to meet the diverse needs of industries requiring automation and precision.

About the Company

Leading Suppiler & Exporter

ISO Certified

Trustseal Verified

Manufacturer

Transportation Mode

Air Transport

Sea Transport

Land Transport

Payment Terms

RTGS

100% T/T

NEFT

IMPS

UPI

Be the first to review “Rotary Indexing Machine Manufacturers in Delhi” Cancel reply

FAQs

Q: What are Rotary Indexing Machines (RIMs) used for?

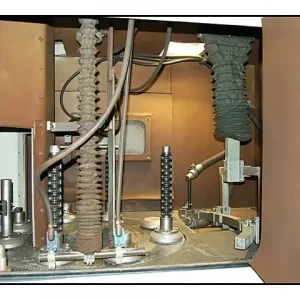

A: Aerowheel’s Rotary Indexing Machines (RIMs, also known as Rotary Table Shot Blasting Machines) are ideal for cleaning and surface preparation of welded structures, fabrications, castings, and other metal parts. They efficiently remove rust, heat scale, casting sand, flash, and other contaminants, leaving a clean and ready-to-paint or coat surface.

Q: How do Aerowheel's RIMs work?

A: Our RIMs operate using the suction blasting principle. Workpieces are loaded onto a rotating table inside a blast cabinet. The table indexes, bringing each workpiece under the blast zone one at a time. A powerful turbine throws abrasive media at the workpiece, effectively cleaning its surface. The used abrasive is then recycled and cleaned for reuse.

Q: What are the benefits of using Aerowheel's RIMs?

High efficiency: Process multiple workpieces simultaneously for faster cleaning times. Versatility: Handles various shapes, sizes, and materials, including fragile components. Superior cleaning: Removes even stubborn contaminants like rust and heat scale. Cost-effective: Durable design with efficient abrasive recycling minimizes operating costs. Customizable: We offer single or dual table options and can design machines to your specific needs.

Q: Why choose Aerowheel as your Rotary Indexing Machine manufacturer in Delhi?

Experience: We have extensive experience designing and manufacturing high-quality RIMs for various industries. Quality: We use only the best materials and components to ensure long-lasting performance. Innovation: We constantly strive to improve our machines with the latest technologies. Affordability: We offer competitive prices and flexible financing options. Support: We provide comprehensive after-sales service and support to ensure your satisfaction.

Related products

- Customized Blasting Cabinets

Suction/ Vacuum Blast Cabinet Manufacturers in Delhi

Rated 0 out of 5Read more - Customized Blasting Cabinets

Abrasive Blasting Cabinets Price and Manufacturer in Delhi

Rated 5.00 out of 5Read more

Reviews

There are no reviews yet.