1. Introduction

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is a process used to clean or etch surfaces by propelling fine particles at high speed against them. This method is widely used in various industries, such as automotive, construction, and marine, to remove rust, paint, and other surface contaminants.

Importance of Sandblasting in Various Industries

Sandblasting plays a crucial role in industries where surface preparation is essential. It ensures that surfaces are clean and smooth, providing the ideal conditions for painting, coating, or further processing. The effectiveness and efficiency of sandblasting make it a preferred choice for industrial applications.

2. Types of Sandblasting Equipment

Overview of Different Sandblasting Methods

Sandblasting can be performed using different methods depending on the specific requirements of the project. The three main types include wet sandblasting, dry sandblasting, and vapor blasting. Each method has its own advantages and is suitable for different applications.

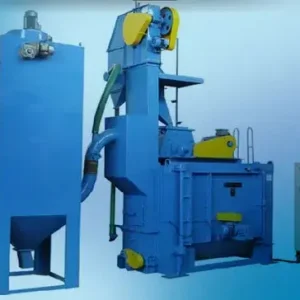

Portable Sandblasting Equipment

Portable sandblasters are compact and easy to transport, making them ideal for small-scale projects or situations where mobility is essential. These units are commonly used for spot cleaning, touch-ups, or maintenance tasks.

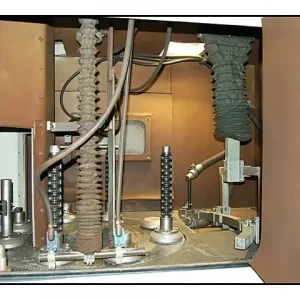

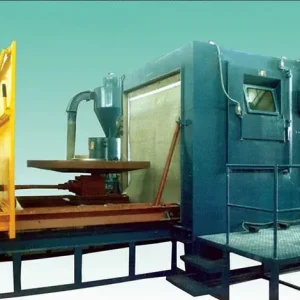

Cabinet Sandblasting Equipment

Cabinet sandblasters are enclosed systems that allow for the recycling of abrasive media. They are often used for detailed work where precision is required, such as cleaning small parts or preparing delicate surfaces.

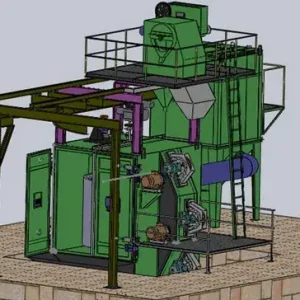

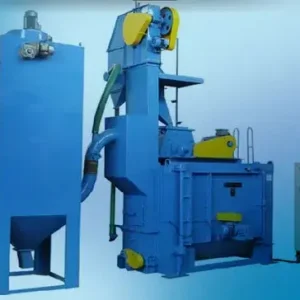

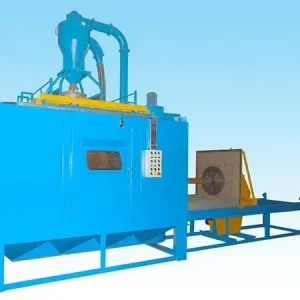

Industrial Sandblasting Equipment

For large-scale industrial applications, heavy-duty sandblasting equipment is used. These machines are designed to handle extensive blasting tasks, often in manufacturing or construction environments, where high productivity is necessary.

3. Key Components of Sandblasting Equipment

Blast Nozzles

Blast nozzles are a critical component of sandblasting equipment. They control the flow and direction of the abrasive media. The material and design of the nozzle can significantly affect the efficiency and effectiveness of the sandblasting process.

Air Compressors

Air compressors supply the necessary power to propel the abrasive media at high velocity. The size and capacity of the compressor must match the requirements of the sandblasting equipment to ensure optimal performance.

Abrasive Media

Abrasive media are the particles used in sandblasting to clean or etch surfaces. Common types include silica sand, glass beads, aluminum oxide, and steel grit. The choice of media depends on the material being treated and the desired finish.

4. Choosing the Right Sandblasting Equipment

Factors to Consider

When selecting sandblasting equipment, several factors must be considered, including the type of project, the material of the surface, and the desired finish. Understanding these elements helps in choosing the right equipment and media for the job.

Matching Equipment to Project Needs

Different projects require different types of sandblasting equipment. For example, a portable unit may be sufficient for small tasks, while industrial projects may require a large, heavy-duty system. Matching the equipment to the specific needs of the project ensures efficiency and effectiveness.

Cost vs. Quality Considerations

While cost is always a consideration, it’s important not to compromise on quality. Investing in high-quality sandblasting equipment can save money in the long run by reducing maintenance costs and improving productivity.

5. Maintenance and Safety Measures

Regular Maintenance Practices

Maintaining sandblasting equipment is essential to ensure its longevity and optimal performance. Regularly checking for wear and tear, cleaning components, and replacing worn parts can prevent costly downtime.

Safety Precautions during Sandblasting

Sandblasting can be hazardous if proper safety measures are not followed. Protective gear, such as gloves, masks, and goggles, should always be worn, and the workspace should be well-ventilated to avoid inhaling dust and debris.

6. Sandblasting Equipment for Specific Applications

Automotive Industry

In the automotive industry, sandblasting is commonly used to remove rust and old paint from vehicle bodies. It prepares the surface for repainting or other treatments, ensuring a smooth and clean finish.

Construction Industry

Sandblasting is widely used in construction to clean and prepare surfaces, such as steel beams and concrete walls. It removes rust, old paint, and other contaminants, making it easier to apply new coatings or finishes.

Marine Industry

In the marine industry, sandblasting is used to clean ship hulls, removing barnacles, rust, and old paint. This process helps maintain the integrity of the vessel and prepares it for repainting or other protective coatings.

Sandblasting Equipment: An In-Depth Guide

Safety Precautions When Operating Shot Blasting Machines

Understanding Shot Blasting Machines: A Comprehensive Guide

7. Environmental Considerations

Managing Dust and Debris

One of the environmental concerns with sandblasting is the generation of dust and debris. Using dust collectors and proper ventilation can help manage this issue, reducing the impact on the environment and the health of workers.

Eco-Friendly Abrasive Media

Choosing eco-friendly abrasive media, such as recycled glass beads or walnut shells, can reduce the environmental impact of sandblasting. These materials are biodegradable or recyclable, making them a more sustainable option.

Regulatory Compliance

Compliance with environmental regulations is essential in sandblasting operations. Companies must ensure that their processes and materials meet the necessary standards to avoid fines and legal issues.

8. Expert Insights

Quotes from Industry Experts

“Choosing the right sandblasting equipment is crucial for achieving the desired results. It’s not just about the equipment itself, but also understanding the material and the project requirements.” — John Doe, Sandblasting Expert

Common Mistakes to Avoid

One common mistake in sandblasting is not matching the abrasive media to the material being treated. Using the wrong media can damage the surface or lead to suboptimal results.

9. Future Trends in Sandblasting Technology

Innovations in Equipment

Advancements in sandblasting equipment, such as automated systems and more efficient compressors, are making the process faster and more precise. These innovations are helping industries improve productivity and reduce costs.

Advancements in Abrasive Media

New types of abrasive media are being developed to offer better performance and lower environmental impact. These advancements are making sandblasting more efficient and sustainable.

Automation in Sandblasting

Automation is becoming increasingly common in sandblasting, particularly in large-scale industrial applications. Automated systems can perform tasks with greater precision and consistency, reducing the need for manual labor.

10. Conclusion

Summary of Key Points

Sandblasting is a vital process in many industries, used to clean and prepare surfaces for further treatment. The right equipment, maintenance, and safety measures are crucial for achieving the best results.

Final Thoughts and Recommendations

Investing in high-quality sandblasting equipment and following best practices can lead to better outcomes and a safer work environment. As technology continues to advance, staying informed about new developments can help businesses remain competitive.

11. FAQs

What is the lifespan of sandblasting equipment?

The lifespan of sandblasting equipment depends on factors such as usage, maintenance, and the quality of the components. Regular maintenance can significantly extend the life of the equipment.

Can sandblasting be used on any surface?

Sandblasting can be used on a wide range of surfaces, including metal, wood, concrete, and glass. However, the choice of abrasive media and equipment should be matched to the material to avoid damage.

How do I know if my sandblasting equipment needs replacement?

Signs that sandblasting equipment may need replacement include decreased efficiency, frequent breakdowns, and visible wear and tear on components such as nozzles and hoses. Regular inspections can help identify these issues early.