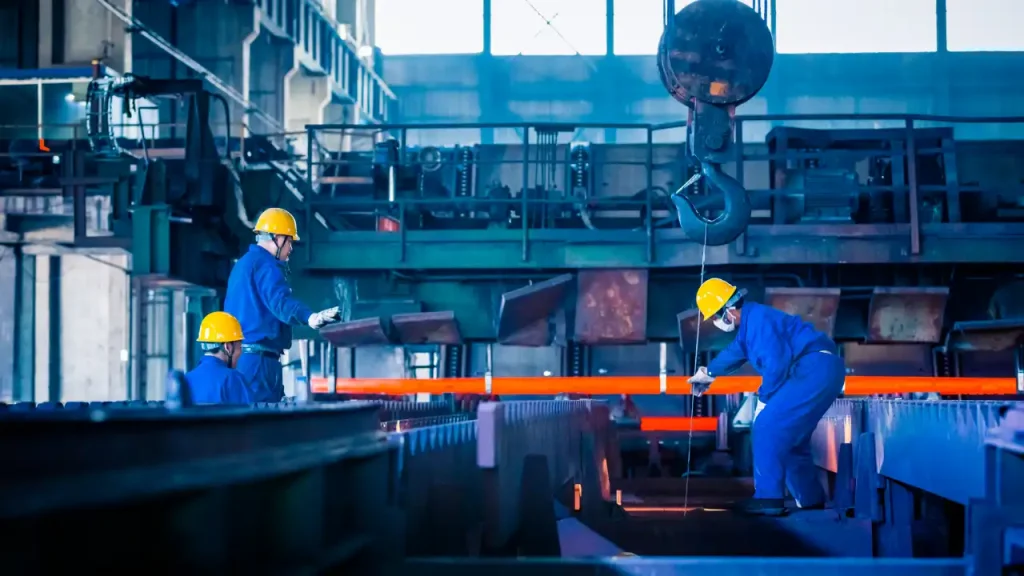

In recent years, environmental sustainability has become a significant focus for industries worldwide, including the shot blasting machine manufacturing sector. Indian manufacturers of shot blasting machines have recognized the importance of integrating eco-friendly practices and technologies into their products. Let’s delve into the insights provided by Indian manufacturers regarding shot blasting machines and environmental sustainability.

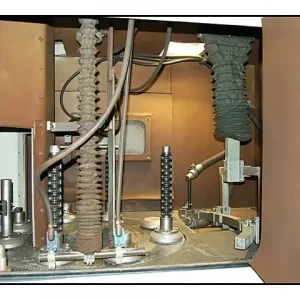

- Dust Collection Systems: Shot blasting processes generate dust and debris that can have adverse effects on the environment and human health. Indian manufacturers prioritize the inclusion of efficient dust collection systems in their machines. These systems capture and contain the generated dust, preventing its release into the atmosphere. By effectively managing dust emissions, manufacturers contribute to a cleaner and healthier working environment.

- Abrasive Recycling: Shot blasting machines utilize abrasive media for surface treatment. Traditionally, this media was discarded after use, leading to excessive waste generation. However, Indian manufacturers have taken significant strides in developing and incorporating abrasive recycling systems into their machines. These systems separate and clean the used abrasive media, allowing for its reuse. By promoting the recycling of abrasive media, manufacturers contribute to reducing waste and conserving resources.

- Energy Efficiency: Indian manufacturers understand the importance of energy efficiency in shot blasting machines. They incorporate energy-saving features, such as optimized blast wheel designs, variable speed drives, and efficient airflow systems. By minimizing energy consumption during the shot blasting process, manufacturers help industries reduce their carbon footprint and operating costs.

- Noise Reduction Measures: Shot blasting machines can generate considerable noise levels, which can have detrimental effects on workers and the surrounding environment. Indian manufacturers focus on developing machines with noise reduction measures, such as sound insulation panels, vibration dampening systems, and efficient exhaust systems. By mitigating noise pollution, manufacturers create safer and more environmentally friendly working conditions.

- Water Conservation: Some shot blasting processes require the use of water for cooling, dust suppression, or media separation. Indian manufacturers have implemented water conservation measures in their machines, such as closed-loop water systems and recycling systems. These systems minimize water consumption, reduce wastewater generation, and promote responsible water usage.

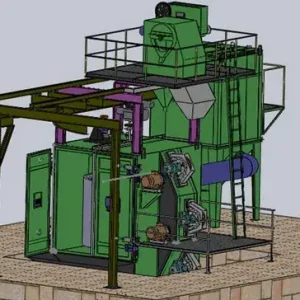

- Compliance with Environmental Regulations: Indian manufacturers of shot blasting machines ensure that their products comply with relevant environmental regulations and standards. By adhering to these guidelines, manufacturers promote responsible manufacturing practices and provide customers with machines that meet industry-specific environmental requirements.

- Continuous Research and Development: Indian manufacturers actively engage in research and development to explore new technologies and processes that enhance the environmental sustainability of shot blasting machines. They invest in innovation, collaborate with industry experts, and seek eco-friendly alternatives in materials and processes. This dedication to continuous improvement drives the development of greener and more sustainable shot blasting solutions.

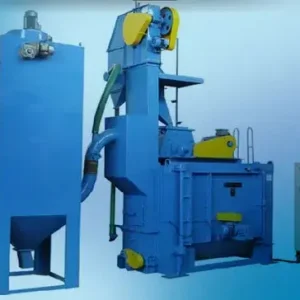

Shot blasting machine manufacturers in India

Indian manufacturers understand that environmental sustainability is not just a trend but a global responsibility. By integrating eco-friendly features into their shot blasting machines, they contribute to reducing environmental impact, conserving resources, and creating a more sustainable future. Through their efforts, Indian manufacturers are leading the way in promoting environmentally conscious practices within the shot blasting industry.

In conclusion, Indian manufacturers of shot blasting machines prioritize environmental sustainability by incorporating features such as dust collection systems, abrasive recycling, energy efficiency, noise reduction measures, water conservation, and compliance with regulations. Their commitment to continuous research and development ensures that shot blasting machines become increasingly eco-friendly. By embracing these practices, Indian manufacturers set an example for the industry and actively contribute to a greener and more sustainable approach to shot blasting.

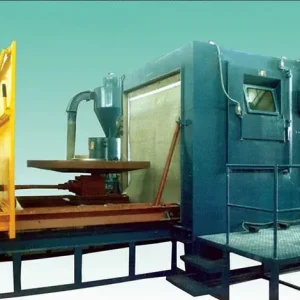

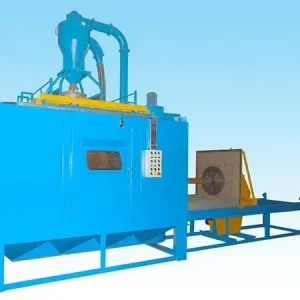

The different types of shot blasting equipment available and their uses

How Leading Manufacturers are Reducing the Environmental Impact of Shot Blasting

Exploring the Wide Range of Shot Blasting Machines Offered by Indian Manufacturers