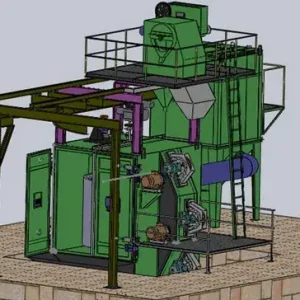

Shot blasting machines have a significant impact on corrosion prevention in various industries, and Indian manufacturers have been instrumental in providing effective solutions to combat corrosion. In this article, we will delve into the role of shot blasting machines in corrosion prevention and explore insights from Indian manufacturers on this crucial aspect.

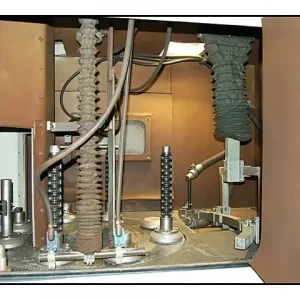

- Surface Preparation: Corrosion prevention begins with proper surface preparation, and shot blasting machines excel in this area. Indian manufacturers offer shot blasting machines that effectively remove rust, scale, and other contaminants from the surface of metal components. By eliminating these impurities, the machines create a clean and properly prepared surface, which is crucial for the application of corrosion-resistant coatings or paints.

- Coating Adhesion: Shot blasting machines play a crucial role in enhancing the adhesion of corrosion-resistant coatings. By roughening the surface through the impact of abrasive particles, the machines create a profile that allows the coatings to bond tightly with the metal substrate. This ensures a durable and long-lasting protective barrier against corrosion.

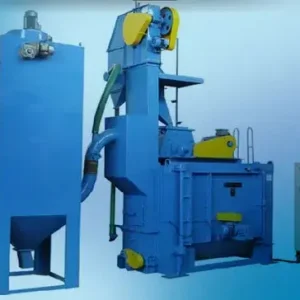

- Removal of Existing Corrosion: Shot blasting machines are capable of removing existing corrosion from metal surfaces. Indian manufacturers offer specialized shot blasting equipment that can effectively strip away corroded layers, revealing a clean and sound metal surface. This process not only improves the aesthetics but also eliminates hidden corrosion spots, preventing its further spread and potential damage.

- Surface Cleaning and Contaminant Removal: Corrosion often occurs due to the presence of contaminants on the metal surface. Shot blasting machines are highly effective in cleaning the surface and removing contaminants such as oils, greases, dirt, and oxides. By eliminating these substances, the machines create a pristine surface that is less susceptible to corrosion.

- Consistent and Uniform Treatment: Shot blasting machines provide a consistent and uniform treatment to the entire surface of the workpiece. Indian manufacturers offer shot blasting systems with advanced control mechanisms that ensure uniform coverage and treatment of the metal surface. This eliminates the risk of untreated or poorly treated areas that could become vulnerable to corrosion.

- Preservation of Metal Integrity: Shot blasting machines, when used appropriately, preserve the integrity of the metal being treated. Indian manufacturers understand the importance of balancing the blasting intensity to remove corrosion and contaminants without causing damage to the underlying metal structure. This careful approach ensures that the treated metal maintains its strength and structural integrity, even after the shot blasting process.

- Extended Lifespan of Components: By preventing corrosion, shot blasting machines significantly contribute to extending the lifespan of metal components. Indian manufacturers’ focus on quality and precision in shot blasting equipment ensures that metal parts and surfaces remain protected against corrosion for a longer duration. This, in turn, reduces maintenance costs, enhances operational efficiency, and prolongs the service life of the components.

- Compliance with Industry Standards: Indian manufacturers of shot blasting machines adhere to international quality and safety standards. They ensure that their machines meet the specific requirements of corrosion prevention in different industries, including automotive, aerospace, construction, and manufacturing. By providing reliable and compliant equipment, these manufacturers help industries meet regulatory guidelines and maintain high-quality standards in corrosion prevention.

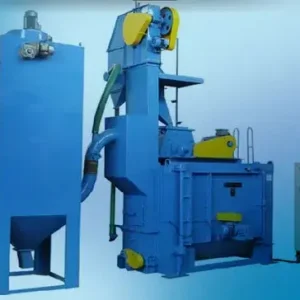

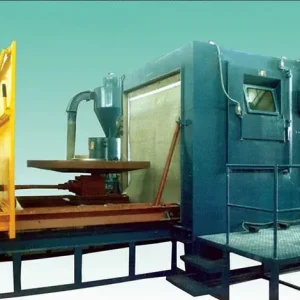

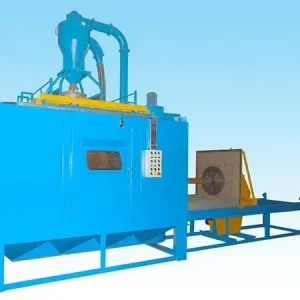

shot blasting machine manufacturers in India

In conclusion, shot blasting machines offered by Indian manufacturers play a vital role in corrosion prevention. Through effective surface preparation, coating adhesion enhancement, removal of existing corrosion, and surface cleaning, these machines contribute to the longevity and integrity of metal components. By delivering consistent and uniform treatment, they ensure comprehensive corrosion protection. Indian manufacturers’ commitment to quality, precision, and compliance with industry standards makes them valuable partners in the fight against corrosion in various sectors.

Blasting Rooms at AeroWheel Surface Finishing: Precision and Quality in Every Detail