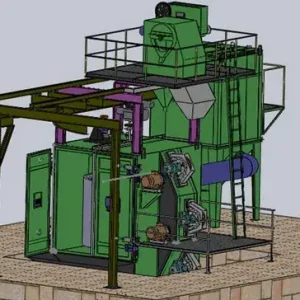

What is a Shot Blasting Machine?

A shot blasting machine is an essential piece of industrial equipment used in various industries to clean, strengthen, or polish metal surfaces. This powerful machine propels a stream of abrasive material, typically steel shots or grits, at high velocity onto the surface of a workpiece. The process effectively removes rust, scale, and other contaminants, leaving the surface clean and prepared for further processing like painting, coating, or welding.

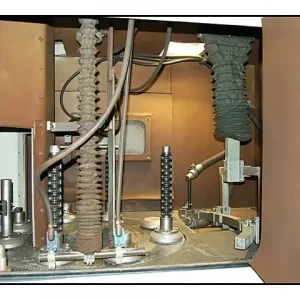

Key Components of a Shot Blasting Machine

- Blast Wheel: The core component of the shot blasting machine, the blast wheel propels the abrasive media onto the workpiece. It consists of blades, an impeller, and a control cage, which work together to regulate the flow and direction of the media.

- Abrasive Media: The choice of abrasive media can vary based on the specific application. Common types include steel shots, steel grits, glass beads, and aluminum oxide. The selection of media affects the finish and effectiveness of the cleaning process.

- Blasting Chamber: This is the enclosed space where the blasting operation takes place. It is designed to withstand the abrasive action and contains wear-resistant materials to prolong the machine’s lifespan.

- Dust Collector: To ensure a clean and safe working environment, shot blasting machines are equipped with dust collectors. These systems capture dust and debris generated during the blasting process, preventing them from contaminating the workspace.

- Elevator and Separator: The elevator lifts the used abrasive media to the separator, where reusable media is separated from the waste. The cleaned media is then recirculated back into the blasting cycle.

Types of Shot Blasting Machines

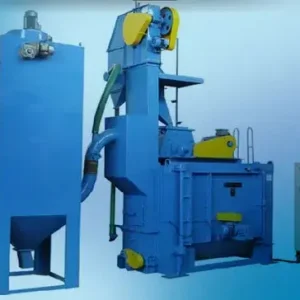

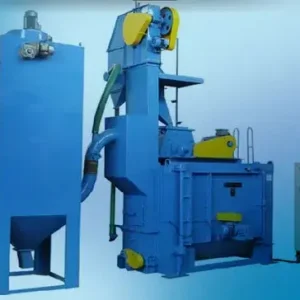

- Tumble Blast Machines: Ideal for processing small to medium-sized workpieces in bulk. The workpieces are loaded into a rotating drum where they are uniformly exposed to the abrasive stream.

- Spinner Hanger Machines: Designed for larger, more complex workpieces. The workpieces are hung on hooks and rotated through the blast stream, ensuring comprehensive coverage.

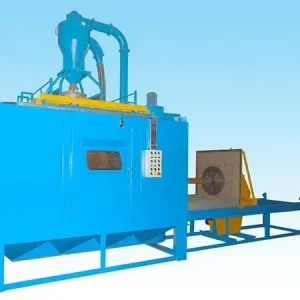

- Continuous Blast Machines: Suitable for high-volume production lines. Workpieces are continuously fed through the machine on a conveyor system, optimizing efficiency and throughput.

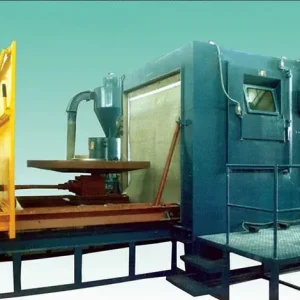

- Table Blast Machines: Used for larger, flat workpieces. The workpieces are placed on a rotating table, allowing the blast wheel to clean all sides effectively.

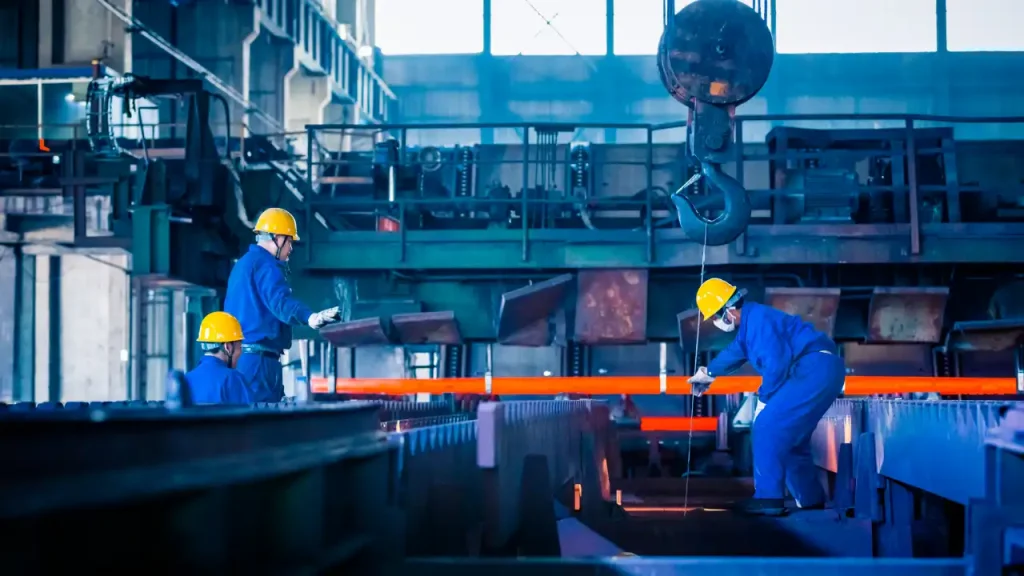

Applications of Shot Blasting Machines

- Surface Preparation: One of the primary uses of shot blasting is to prepare surfaces for subsequent coating processes. The clean, roughened surface ensures better adhesion of paints, coatings, or adhesives.

- Rust and Scale Removal: Shot blasting is highly effective at removing rust, mill scale, and other surface contaminants from metal surfaces, restoring them to their original condition.

- Deburring and Deflashing: In manufacturing, shot blasting is used to remove burrs and flash from cast, forged, or machined parts, ensuring a smooth finish.

- Peening: Shot blasting can also be used for shot peening, a process that enhances the mechanical properties of metal parts by inducing compressive stresses, improving fatigue resistance and lifespan.

Advantages of Using Shot Blasting Machines

- Efficiency: Shot blasting is a fast and efficient process, capable of cleaning large surfaces quickly compared to other methods like manual sanding or chemical cleaning.

- Versatility: The ability to use different types of abrasive media allows for flexibility in achieving various surface finishes and meeting different cleaning requirements.

- Cost-Effective: By reusing abrasive media and minimizing waste, shot blasting is a cost-effective surface treatment solution. Additionally, it reduces labor costs and increases productivity.

- Environmentally Friendly: Modern shot blasting machines are designed with dust collection systems that minimize environmental impact and ensure a safer working environment.

Conclusion

A shot blasting machine is a vital tool in industrial manufacturing and maintenance. Its ability to clean, prepare, and enhance metal surfaces makes it indispensable in industries such as automotive, aerospace, construction, and shipbuilding. Understanding the components, types, applications, and benefits of shot blasting machines helps businesses choose the right equipment for their specific needs, ensuring optimal performance and quality in their production processes.

By leveraging the advantages of shot blasting machines, companies can improve their product quality, extend the lifespan of their metal components, and achieve greater efficiency and cost savings in their operations.

Conquer Large-Scale Blasting with AeroWheel: Your Jodhpur Tunnel Type Shot Blasting Machine Experts